GRE Pipe Production Line for Marine & Petroleum Field

We adopt the most advanced technology for GRE pipe production line, which offers the best efficiency and quality GRE pipes.

GRE pipe production line could offer quality GRE (glass resin epoxy) pipe for seawater pipeline. We take high strength fiber-glass and epoxy resin by specific winding technology. GRE pipes have distinct advantages over other pipes in marine and petroleum fields as they could bear high pressure and have long service life.

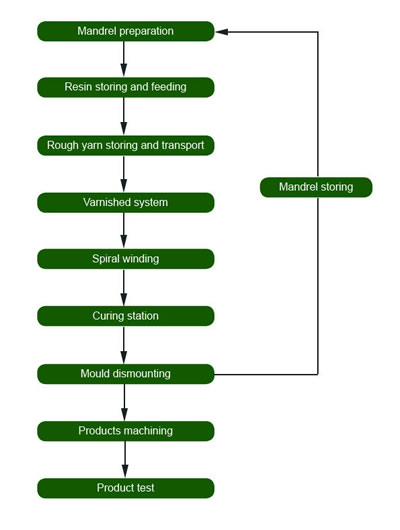

GRE pipe production line is shown above, it is also the operational path of GRE pipe manufacture.

Main components:

- Mandrel storing system.

- Mandrel.

- Cleaning station.

- Heat booster.

- Resin processing and storage system.

- Winding machine.

- Curing station.

- Mould dismounting machine.

- Trimming machine.

- Hydraulic pressure tester.

- Electricity distribution system.

- Creel station.

- Rail transportation equipment.

Specification

- Machine model: GYFC-600.

- Pipe diameter: DN 80-600 mm (3" to 24").

- Pipe length: 9 m.

- Yarn feeder speed (max): 1 m/s.

- Accuracy: > 0.3 mm.

- Yarn feed speed (max): 75 m/min.

GRE pipe connection methods

- Bell and spigot joint.

- Double o-ring joint.

- Flange joint.

GRE pipe application

- Firewater system.

- Salt water supply lines.

- Cooling water.

- Waste lines.

- Potable water.

- Process lines.

- Ballast piping.

- Sprinkler system.

- Cargo lines.

- Bilege piping.

- Sounding tubes.

- Scuppers.

- Fresh water lines.

- Sanitary lines.

- Vent lines.

- Oil gathering line.

- Petroleum chemical lines.

Product List

- Liner Making Machine

- Discontinuous Filament Winding Machine

- Curing Station

- Trimming Machine

- Extraction Machine

- Pipe Hydro Tester

- Microcomputer Control System

- Precast Pump Station Production Facility

- FRP Double Tank Spray Device

- FRP Cellular Anode Tube Equipment

- Cable Pole Production Equipment

- FRP Pole Winding Device

- Insulation Pipe Spraying Equipment

- Power Pipe Winding Machine

- Lightning Arrester Winding Machine

- Cantilever Winding Machine

- 4V Gas Cylinder Winding Machine

- 4V Gantry Type Gas Cylinder Winding Machine

- 4V Cone Type Tube Winding Machine

- Power Casing Winding Machine

- Double Wall Tank Spraying Equipment

- Two Spindles Winding Machine

- Multiple Spindles Gantry Type Winding Machine

- Multiple Spindles Horizontal Winding Machine

Copyright © Hengshui Fangchen FRP Equipment Technology Co., Ltd.

Add: No.6 east of Rubber Road, Northern Industry Area, Hengshui, Hebei, China.

TEL: +86-318-2996366

Website: www.frpmachine.com

E-mail: info@frpmachine.com

Links: