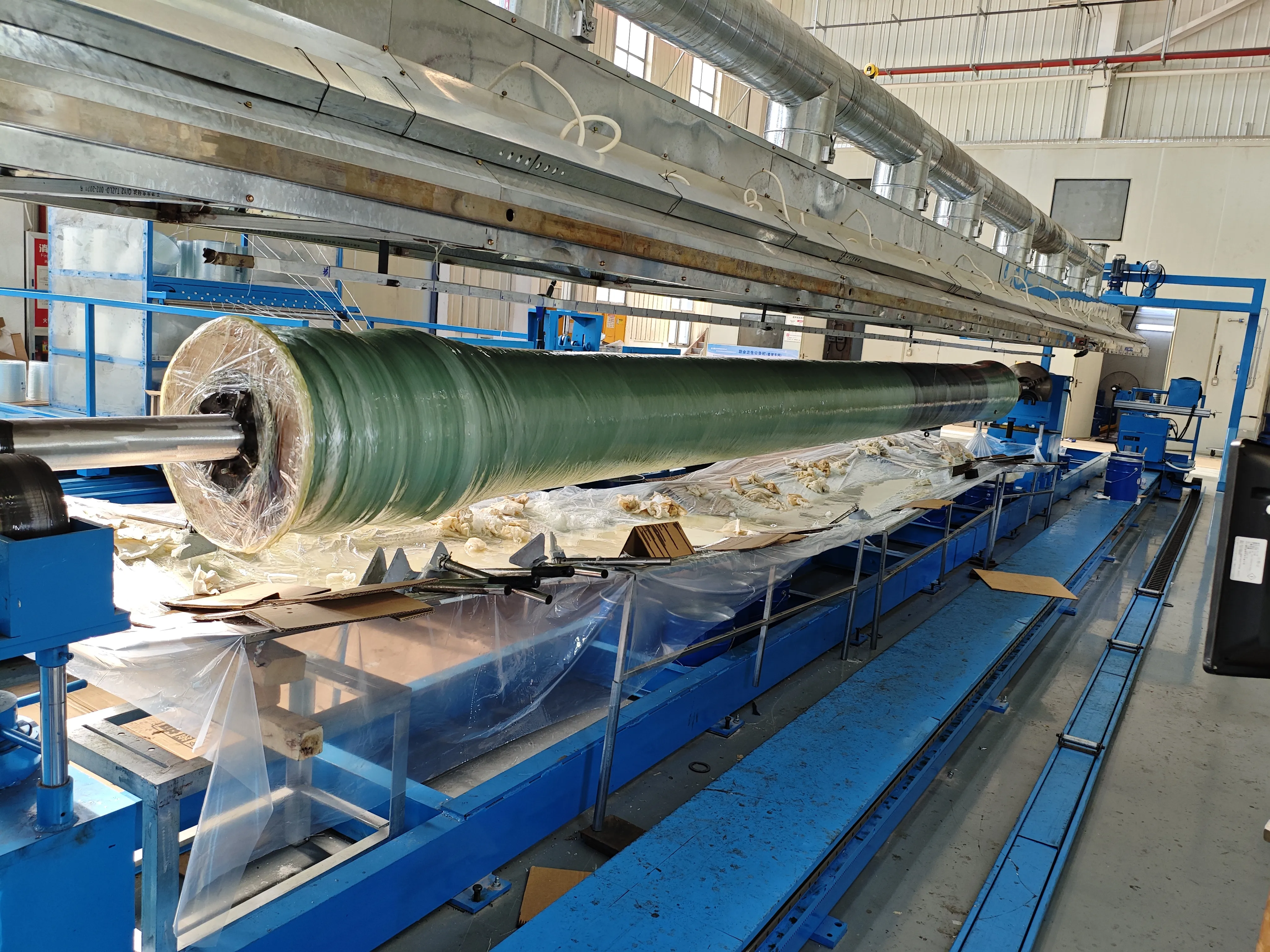

Wall-penetrating sleeve winding equipment

In order to meet the quality requirements for the winding of through-wall sleeves and in accordance with the relevant requirements of the process for horizontal winding equipment.

Winding Parameters:

- Winding Dia Range: 50-300mm, Length 6000mm

- Yarn arrangement accuracy: ±0.5mm

- Winding Angle: 45°-90°

- Yarn drawing speed: ≤80m/min

- Winding method: Spiral, circumferential (Spiral and circumferential can be automatically switched)

- Control mode: Manual, automatic

- Yarn drawing method: Linear yarn drawing

- Transmission method: Rack drive + linear guide rail

- The length of the wound product (L), the width of the yarn (B), the winding Angle (a), and the end dwell length (c). After the winding length (L) is fixed, two of the remaining three parameters can be arbitrarily locked to remain unchanged.

- Winding can be carried out respectively from the end or tail of the product as the winding zero point

- It can directly switch from single-layer circumferential winding to helical winding

- Yarn width: 10mm to 80mm 13. Maximum speed of the trolley: 50m/min

- Wrapping machine form: Horizontal two-dimensional wrapping, wrapping one piece at a time.

- At the lower end of the winding machine shaft head, there is a core mold pause frame, which can be temporarily placed on the core mold.

- The temperature measurement points of the winding glue tank are set in the resin glue liquid area, and the monitoring range of the glue liquid temperature is 30-50℃

Product List

- Liner Making Machine

- Discontinuous Filament Winding Machine

- Curing Station

- Trimming Machine

- Extraction Machine

- Pipe Hydro Tester

- Microcomputer Control System

- Precast Pump Station Production Facility

- FRP Double Tank Spray Device

- FRP Cellular Anode Tube Equipment

- Cable Pole Production Equipment

- FRP Pole Winding Device

- Insulation Pipe Spraying Equipment

- Power Pipe Winding Machine

- Lightning Arrester Winding Machine

- Cantilever Winding Machine

- 4V Gas Cylinder Winding Machine

- 4V Gantry Type Gas Cylinder Winding Machine

- 4V Cone Type Tube Winding Machine

- Power Casing Winding Machine

- Double Wall Tank Spraying Equipment

- Two Spindles Winding Machine

- Multiple Spindles Gantry Type Winding Machine

- Multiple Spindles Horizontal Winding Machine

Copyright © Hengshui Fangchen FRP Equipment Technology Co., Ltd.

Add: No.6 east of Rubber Road, Northern Industry Area, Hengshui, Hebei, China.

TEL: +86-318-2996366

Website: www.frpmachine.com

E-mail: info@frpmachine.com

Links: